Temperature Technology manufacture and import a selected range of instruments for measuring and monitoring of temperature and related physical quantities, pH, mA, RH. These include thermometers, dataloggers, circular chart recorders and refrigerated vehicle (for trucks and vans) recorders with printing ability. Our selection criteria include price, accuracy, resolution, usability and durability, based on more than 70 years combined experience with temperature measurement and monitoring. More about Temperature Technology.

Find out more in What's in it for me?

You can with TempReport! Would you like to try TempReport before committing to the purchase of software and equipment?

Wireless data logging using radio frequency at 433MHtz, with a range of 350 meters with standard equipment (range can be extended with antennae and repeaters). The T-TEC C, E and F all have wireless counterparts. It's so new, not all of the data is on the website, yet.

See it in our video!

Latest version of our software is T-TEC 15.7 This version solves problems for USB 06 cables with version numbers less than 1.4. It also removes the appearance of a failed driver install (the driver pre-installed just fine).

Our data loggers are battery powered measurement instruments with memory for unattended monitoring of temperature. To start the logging and to download the result, the data loggers are connected to PCs via interface cables. Graphic software provides options for initial setting and for extracting information.

T-TEC data loggers are the optimal choice due to the latest technology, unique design and powerful user friendly software. With the exception of the humidity loggers, all t-tec dataloggers are IP68 waterproof. All T-TEC data loggers are encased in a polycarbonate casing that is both durable and strong. Put in anywhere with the optional wall bracket and get all the detailed information on your screen. Curves from up to 8 different locations / data loggers may be called up simultaneously. All T-TEC Data Loggers have an LCD display as an optional extra.

The classic T-TEC loggers are started up by being connected to a USB port, started with the desired measuring intervals, then put in the place where the temperature needs to be monitored. After the event, the data logger is retrieved, taken back to the computer and the file downloaded, scrutinised and perhaps printed. Alarms may be set. They can be seen or heard on the logger.

This is suitable for circumstances where there is no need for alarms or where the data logger is not needed there permanently: monitoring air conditioning when there is a complaint, refrigerators and freezers under repairs, fields that may be suitable for certain crops. They provide a reliable history of the temperature movement.

The wireless T-TEC data loggers are actively listening for demands from the gateway and responding accordingly, sending temperature updates and downloading files at user selected intervals. They are also contacting the gateway if there is an alarm triggered in the logger. This message is in turn used to alert the user in several ways. Alarm info may even be sent to the cloud and seen from anywhere in the world. Wireless data loggers are typically chosen to monitor critical temperatures in permanent settings: In refrigerators, freezers and cool rooms and storage with valuable perishable contents. They save time and effort in places that are hard to access, in trucks and vans where the download can happen automatically on return to the yard, and they enhance the security considerably.

A printable data sheet with an overview of T-TEC dataloggers.

Founded in 1982 by Managing Director Kirsten Blichfeldt and Operations Manager Hans Blichfeldt, Temperature Technology is a manufacturer and supplier of instruments and measuring devices for temperature and related quantities.

We are based in Adelaide, South Australia.

Over the years, we have developed specialised skills in the temperature measurement and monitoring area, and we take great pride in offering:

Manufacture quality products and supply service which without exception meet customer and regulatory specifications.

The supplier of choice for our customers.

| Casing | Polycabornate, watertight to IP68 Humidity loggers splash proof from top |

|---|---|

| Size | 65 × 31 × 106 mm |

| Weight | 115 g |

| Ambient | -40 + 85 °C |

| Battery | 1 × ½AA, 3.6V |

| T-TEC 6: Expected battery life: 3-4 years | |

| T-TEC 7: Expected battery life: 2 years, Low battery warning on display | |

| Sensor (see sensor specifications) | Temperature: Precision Thermistor or Pt100 |

| Humidity: capacitive precision | |

| Memory | E model: 12,000 to 25,000 sets of measurements |

| C model: 10,600 sets each sensor | |

| F model: 10,600 sets each sensor (21,200 if only one) | |

| A & P: 20,000 to 60,000 sets of measurements | |

| Interface | Special interface cable to serial port and/or special interface cable to USB Port |

| Security ID | Permanent serial number |

| Warranty | 1 Year (not incl. sensor) |

| Resolution | Temperature: Better than 0.1 °C (see sensor specifications) |

| Humidity: Better than 0.1%RH |

When starting the logging, one or two alarms may be set as minimum and/or maximum alarms. A period of grace may be set in minutes. Alarms can be programmed to reset themselves once a day at a chosen time. Type C loggers (For temperature and Humidity) have alarm functions for temperature only.

Some types may be supplied with optional relay output. Change-over relay, all three contacts available. Contacts: Gold clad silver contacts. Nominal switching capacity (Resistive load) 1A/30V DC, 0.5A 125V AC

| Casing | Stainless Steel, Polypropylene seal |

|---|---|

| Size | 17.35mm diameter 5.9mm height |

| Weight | 3.2 g |

| Ambient | -40 to 85 °C. Should not be exposed to temperatures in excess of 70 °C for prolonged time. |

| Battery | Built in: Non-replaceable |

Estimated life time: 5-7 years, depending on:

|

|

| Sensor | Built in, semiconductor |

| Memory |

DS1921: 2,048 logs DS1922: 4096 or 8192 (depending on resolution) DS1923: 2,048 or 4,096 (depending on resolution) |

| Interface | |

| USB adaptor | |

| Security ID | Engraved unique serial number on case. This number also embedded in internal electronics. |

| Resolution | 1921: ±0.5 °C |

| 1922: ±0.5 °C (low resolution) or ±0.0625 °C (high resolution) | |

|

1923: ±0.5 °C (low resolution) or ±0.0625 °C (high resolution) |

|

| Accuracy | ±1 °C from -20 + 70 °C, at time of calibration at factory. |

| Time Accuracy | Maximum 8 minutes minutes per month over full temperature range. |

Thermochron is a registered trademark of Maxim Integrated Products.

| Range | Accuracy |

|---|---|

| -40 to 0 °C | ± 0.3 °C |

| 0 to 70 °C | ± 0.2 °C |

| 70 to 85 °C | ± 0.3 °C |

| 85 to 100 °C | ± 0.5 °C |

10-90 % ± 2% RH, Compensated for -5 + 60 °C ambient temperature

Two different external temperature sensors available

| Type | Ranges | Resolution | Accuracy | |

|---|---|---|---|---|

| T1 | - 40 to 85 °C | < 0.1 °C | As for built in sensor | |

| T2 | -100 to 20 °C | < 0.1 °C | -90 to 20 °C ± 0.8 °C | |

| -100 to -90 °C ± 1.0 °C | ||||

Four different temperature ranges available.

| Type | Ranges | Resolution | Accuracy |

|---|---|---|---|

| A | -200 + 120 °C | 0.2 °C | -200 - 100 °C ± 2.0 °C |

| -100 - 40 °C ± 1.0 °C | |||

| -40 + 120 °C ± 0.5 °C | |||

| B | -40 + 120 °C | 0.1 °C | -40 + 120 °C ± 0.3 °C |

| C | -40 + 280 °C | 0.2 °C | -40 + 100 °C ± 0.4 °C |

| +100 + 200 °C ± 0.6 °C | |||

| +200 + 280 °C ± 1.0 °C |

Accuracy: ± 1% of range

Connection through supplied 2 meter cable with connector for logger.

Synchronisation up to: ± 1 second; ± 1 minute per month.

In the course of our more than 20 years of experience dealing with customers in the temperature measuring industry, we have found that particular situations and logical solutions often recur. To help our customers find what they need as quickly as possible we have listed some of these situations and our solutions to the left, grouped by logistical category.

From 60 C to 21 C in a maximum of 2 hours

From 21 C to 5C in a maximum of 4 hours

With the T-TEC wireless data loggers you can now be informed of how the cooling is progressing in real time. You can print the graph later for proof.

Using the advanced alarm settings it is even possible to be told if the prescribed cooling requirements are NOT met, so that you can quickly do something about it.

Records of temperatures during smoking or cooking are most important for proof of each batch having been at the correct temperature for the prescribed time.

If the meat is overcooked weight loss occurs as well as loss of quality, and if it is undercooked, harmful organisms may survive.

The T-TEC 6-3E with watertight sensor inserted into the core of the meat is the ideal way to monitor the process. The data logger itself can be mounted on the trolley, so that there is no risk of accidentally tearing the sensor.

Electronic humidity sensors do not work well in smoking ovens.

The best way of getting the relative humidity is to use a T-TEC 6-3F Data logger for 2 remote sensors. One sensor is kept moist by a hygroscopic 'stocking' (wet bulb)and the other measures the air temperature (dry bulb). By comparing the two readings, taken at the same time, it is possible to calculate the relative humidity, using a table.

To test the cooking times and temperatures, it is possible to insert a Thermochron into the center of the pie and let the pie go through the baking process. When downloaded it is easy to see, if the time / temperature is correct.

Air conditioning often feels too warm or too cold. A good way to minimise complaints is to show the customer precisely what is happening over time in the disputed area. One or two T-TEC 6-1E Data loggers (or T-TEC 6-1C if humidity is involved) placed in the room for a week, logging every minute will show exactly what happens.

Depending of the size and number of rooms , many data loggers may be needed to provide evidence of how a system works in all spaces simultaneously.

T-TEC 6-1E Data loggers are accurate and reliable. Thermochrons may be an economical alternative, if the accuracy of ±1 °C is acceptable.

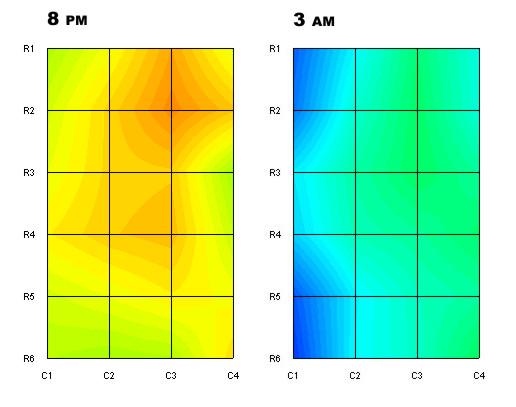

If the area is one large space, the readings of minimum 9, preferably more, data loggers may be loaded into DyMap:Dynamic Mapping Software for visual representation of the many graphs in moving colours. Using Dymap, it is easy to see where the heat comes from and when and where it is lost. Dymap works with T-TEC, Thermochron and other data loggers, if the file format is suitable.

The T-TEC 6-1E Data logger for outdoor use can be set so that it tells whether the orange orchard has suffered too much frost for the oranges to be accepted for export. The alarm thresholds & grace periods can be set in the data logger, which will then beep if the frost has been too hard over night. The data logger can automatically reset itself once daily.

The T-TEC 6-1E Data logger is suitable for outdoor use and can monitor for a year if set to log once an hour. For the best readings some shade should be provided: the canopy of a tree or an upturned bucket will do.

T-TEC 7-3E with display so that the temperature can be seen as well as logged, with a sacrificial sensor is the ideal way to monitor the temperatures after pouring of the concrete. Sacrificial sensors are simple wire sensors with precision thermistor, which may be cut and left when the test is over.

T-TEC 7-3E Data logger and 1m long stainless steel probe with teflon cable are ideally suited to monitor the temperature in compost heaps. The data logger has 2 alarm settings and options for grace periods. On the display it will show A1or A2 when the set temperature has been maintained for the set amount of time.

T-TEC 6-3A and T-TEC 7-3A Data logger for mA input accept input from any transmitter that gives out a 4-20mA signal. The software allows for scaling and calibrating so that the display can show the actual units measured (ie. 2 to 12 pH).

If a record is needed on the spot, the TT260 Chart recorder can write the graph on a circular chart. The TT260 has options for alarm contacts and battery back-up.

"The most common problem is the temperature monitoring and alarm system"

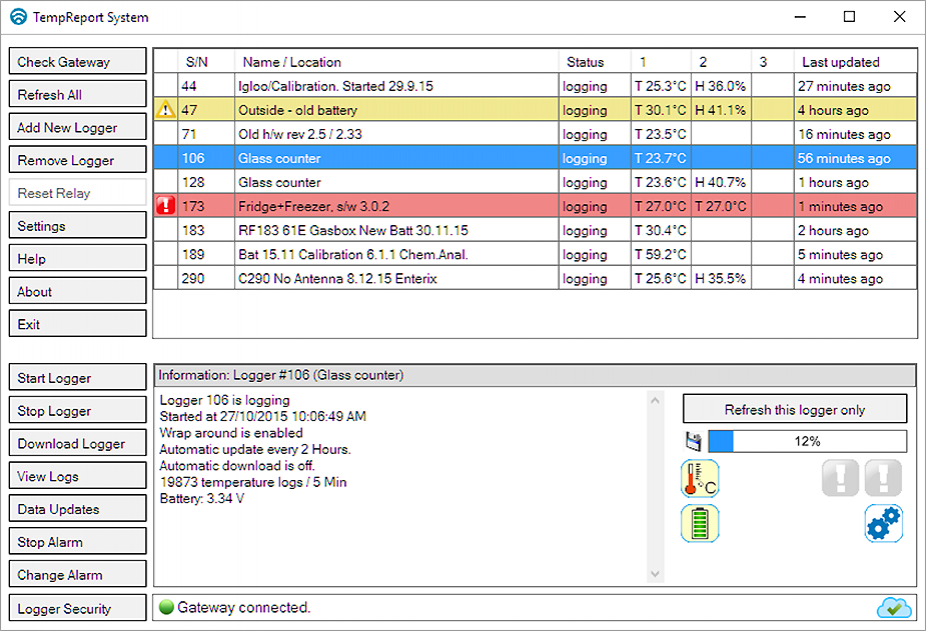

With wireless T-TEC Data loggers monitoring the temperature inside the refrigerator you can get real time updates, get alarm messages and print out graphs.

The actual temperatures from refrigerators and freezers appear on the TempReport screen. The temperature file is kept in the data logger and can be accessed at any time. When downloaded it is kept in the local database, and sent to the cloud, if desired. Alarms may be sent to email & SMS as well.

TT260 Chart recorder with optional alarm contacts and Battery back-up has a chart especially for blood refrigeration TTC 20.5-7S, which is accepted by the TGA.

For Blood product freezers, the chart is TTC 0.45-7L with A line at 25 °C as requested by the TGA.

A RT-3 thermometer is flat, safe and inexpensive yet accurate and very easy to read when the esky is opened. Available for the range of 0 to +12 °C.

Monitoring of daily cycles in refrigerators and freezers is easily done with the EMT888 Min/Max thermometer. The display will show the actual temperature as well as the minimum and maximum recorded since last reset.

The T-TEC 7-3PD Data logger with the range of 0 +150 C and a remote Pt100 sensor is ideal for monitoring the process of sterilisation and providing proof of correct temperatures obtained. Data logger can log once a second to document the time versus temperature for fast procedures. Special sensors made to order.

Baby bath thermometer made with liquid crystal thermometer laminated in water proof flexible plastic can be made to order after your artwork. The thermometer helps new parents to understand the importance of preventing scalding. The thermometer can be made for other age groups as well, older children, aged care and birthing baths.

T-TEC 7-3E Data logger with display and remote sensor can be mounted in a bracket (can be padlocked) outside with the sensor going into the cool room. Relay output if necessary.

The T-TEC 6-1C or T-TEC 7-1C Data logger with external sensor for humidity and internal sensor for temperature complies with the strictest requirements. The casing is closed so the data loggers can tolerate high humidity in the incubator or climate chamber. If temperature changes are happening fast, the T-TEC 6-2C or T-TEC 7-2C with fixed external temperature sensor should be chosen.

The freezer can be monitored by a TT260 Chart recorder temperature range: -110 to -200 °C. The TT260 with 7 days rotation can be equipped with battery back-up and alarm contacts. Available for panel or wall mounting

Alternatively, the Data loggers: T-TEC 6-3PA or T-TEC 7-3PA (display) with a temperature range of +20 to -200 °C if download to a PC is the preferred way to read and store the results.

The T-TEC 6-3E or T-TEC 7-3E (display) can connect the 'Petridish sensor', which is 1 × 3mm and will fit into a small vial or a petri dish.

Monitoring of daily cycles in refrigerators and freezers is easily done with the EMT888 Min/Max thermometer. The display will show the actual temperature as well as the minimum and maximum since last reset.

TT210 Temperature recorder has a Pt100 temperature sensor, is very accurate and has 2 temperature ranges. Because it is battery driven, it can be put exactly where it is needed, each time.

The TT202 Temperature chart recorder gives an accurate reading of the temperature cycles over time. Because it is battery operated, it may be left inside the fridge or freezer over night and the graph is produced then and there.

An even more accurate graph is made by the TT210, which has a remote Pt100 sensor, which can go into the appliance through the seal.

T-TEC Data loggers are also excellent monitors of fridges and freezers, but require the use of a PC or laptop to start and download the readings.

The T-TEC 6-1F Data logger with 2 channels can be used to test both the fridge (where the logger itself is put, using the internal sensor) and the freezer, (where the remote sensor is placed) at the same time.

The T-TEC 6-2E Data logger is water tight and perfectly suited to monitor the temperature variations inside domestic dishwashers. The data logger is placed inside the dishwasher while it washes.

Commercial dishwashers that take in hot water and wash for a very short time are best monitored with T-TEC 6-2E Data Logger with fixed external temperature sensor, logging once every second.

When sending perishable goods, small Thermochron data loggers can be put into strategically chosen boxes clearly marked with Alert Tape. The Thermochrons are easy to return to shipper if they are put in fobs tied to tags with return address. And they are not so expensive that it would be a disaster to lose one.

Thermochron Data loggers, wall mounted inside the cool Room can be easily downloaded once a week by touching them with the TempTec-R reader. The Thermochrons will keep logging, and their files downloaded all in one go to the office computer. The files can be sorted, graphed and scrutinised in the T-TEC software. With a minimum of 9 Loggers in the same coolroom, the readings can even be shown as a movie in DyMap.

The TT202 temperature chart recorder, self contained and mechanical, battery driven can be put on a shelf inside the cool room. The chart must be changed once a week.

The T-TEC 6-1RE datalogger with relay output can activate an alarm — visual, audible or a telephone dialer. The data logger can be set with maximum or minimum alarms and grace periods before alarms are activated.

Thermochrons may be checked and the file downloaded at critical control points by touching them with the TempTec-R Reader, which cannot disturb the logging. The T-TEC software sorts the files according to date, alarms triggered, 4 codes entered into the file, (Name of shipper, product, consignment no. or other code). Files can be saved, emailed or printed, but the logging goes on for as long as the shipper intended.

Again, with a touch of the TempTec-R Reader the Thermochrons are checked for alarms and the files downloaded. The Temp-Tec-R will show on the spot if the temperature has been out of range, (excluding the grace period entered in the Temp-Tec Reader.) Thermochrons are then returned to shipper.

TranScan Sentinel Temperature Recorders for refrigerated trucks. This recorder is wall mounted inside the cabin, so the driver can see the temperatures of 2 sensors, one in the return air and one along the ceiling ¾ way down. With printer for Delivery tickets and journey tickets, so regardless where the truck is, the driver can always prove correct temperatures were maintained. The memory holds five months of data.

TranScan 2-ADR in outdoor weather-proof casing, mounts on the front of the trailer. Can connect up to four temperature sensors and on/off sensors. Includes printer for Delivery and Journey tickets, so that the driver can prove to the customer at delivery points that temperatures were maintained. This model can connect via RS232 port to Navman and other GPS system for automatic and prompted downloads of temperature files to head office regardless of position.

T-TEC Wireless data loggers can be fixed mounted in the truck, van or trailer. At arrival back into the yard, the day's recordings can be transmitted by radio to the gateway. The gateway is connected to a computer that receives the logs and adds them to the database. The logger stays in place, making the task much easier and safer.

The simplest method of complying with regulations, is the T-TEC 6RF-1E Data logger with internal sensor, which can be mounted on a bracket in the return air.

T-TEC 7-3F data logger with display and 2 remote sensors may be placed in the cabin with one sensor mounted in the return air and the other mounted above the goods. Display shows alarm, if the temperature has come out of range. This logger also comes in a wireless version.

RT-602 electronic probe thermometer is handy to have if a customer insists on checks of core temperature of products. The RT-602 has self calibration feature and tapered stem for quick readings.

For fruit export cold treatment may be required by AQIS as described in this PDF:

On-shore Cold Treatment Facility Requirements for Thailand

The cold sterilisation can happen either in a refrigerated container or in a coolroom. The T-TEC Data loggers are suitable for this use as they have fixed serial numbers and high accuracy.

The requirements are: 6 units of T-TEC 7-3E Data loggers with display and sensors long enough to go through the seal into the coolroom are required. 2 sensors must be in the air: one in the air inlet and one in the outlet. Four sensors must be in the core of the fruit, in specified locations.

When the loggers are started, the intended location of each logger must be entered into the file. In the software the logging may be set to every 5 minutes. This will give more than one month worth of data. The alarms may set, so that the logger display can show when the sterilisation is successfully done.

The printout of graphs or files show serial numbers, locations and temperature versus time.

The key to maintain the desired temperature or temperature/humidity in the store or warehouse is being able to know what is happening, when and where . Constant values are hard to maintain in large open spaces. During the year the conditions change in the environment, so it is important to keep an eye on the temperatures. Many factors influence temperature fluctuations:

1. Outside temperatures, sun and wind

2. Temperature bridges in the construction

3. Location of inlet and return air

4. Placing and size of fans

5. Shelving and pallets

6. Doors and loading docks

7. Intake of warm product

8. Warm air moving upwards

For the best understanding of temperature and humidity movements , it is necessary to monitor the area using a number of data loggers. How many loggers are needed, depends on the size and height of the area and the kind product stored. It may desirable to monitor in two or three levels.

Using wireless T-TEC Data loggers has the advantage that once the loggers have been placed permanently, they will stay in place and report back to the computer. The wireless data loggers can send real time temperature updates as well as file downloads. They will need new batteries only once a year in normal use: Logging every 15 minutes with automatic reporting of actual temperatures once an hour and file downloads each week.

The files are seamlessly collected in the database in the computer. It is also possible to send the files to the cloud. The data loggers can send alarms to the computer, if a minimum and maximum temperature level has been set.

Setting up the system is easy, as there is little or no wiring needed. The data loggers can be fastened to a wall bracket, hung or just put on a shelf. The transmission from all the data loggers goes via radio to one or more gateways. In a warehouse it may be necessary to have more than one gateway to contact all the loggers. Larger antennas may also do the trick,

Each gateway needs to be connected to a mobile phone charger for power. The easiest way to communicate with the gateway/s is via WiFi or wired LAN to the PC or the internet.

When planning the layout of the data loggers, it is helpful the make an imaginary grid of rows, columns and layers. When starting the data logger, the specific location should be entered in the location field, for instance R1C2L3. The logger is then marked with this location, to make sure it is placed in the right spot - it also a good idea to label the spot with the data logger number. Using DyMap Software it is then possible to combine the readings from all the loggers for a chosen period into a map of moving colours, which clearly show how the temperature changes over time. Files can also be imported into spreadsheets.

T-TEC Data loggers are made to the highest standards and accuracy. The casing is sturdy and durable and of food grade plastic. There are many models to choose from, with or without display, internal or connected sensor, internal or external antenna.

Temperature Technology offer NATA traceable calibrations and replacement of batteries at a very reasonable price.

T-TEC data loggers are operated via the T-TEC Software. Operations include start, stop, download and graphing functions.

T-TEC software will run under all Windows systems known to date: Win 3.1, 95, 98, ME, 2000, NT, XP, Vista and Windows 7, 8 & 10.

CD Drive, serial or USB port, and about 3MB of free hard drive space. Interface to PC either through T-TEC cable for serial port or T-TEC cable for USB port on computer. T-TEC 501 type B dataloggers can not be contacted via USB port.

T-TEC software is being updated when needed. Current version is 15.2, which supports USB port and Windows 10. New versions of the software still support older model of data logger. T-TEC 501 data loggers can not be contacted via USB port.

The T-TEC software is available for free trial. A trial version may be opened 10 times. To buy or register the software, contact your local distributor (or us) for your registration key. Once registered, the software will display the name of the owner of the licence. The trial version will also update an existing older program.

iButton thermochron loggers, with their interface and the TempTec-R Reader, can also be operated via the T-TEC software.

View T-Tec Software

Dynamic Mapping or profiling is a new concept in the temperature measurement area. The T-TEC DyMap program creates a dynamic visualisation of the result from many dataloggers, constructing a form of movie which shows the total situation, within a certain process, area or room. Data loggers may be positioned in 2 or 3 dimensions.

Win98 or later, incl. XP, VISTA and Win 7, 8 & 10.

Monitor resolution of 800 * 600 or better. For a graph with a large number of different colors, it may be necessary to increase the colour depth to 32 bit colours. 256 Mb RAM or more is recommended.

The program allocates memory dynamically, and in theory, there should not be any limitations of the number of loggers which could be included or the number of measurements in each logger.

Can be used with any data source

DyMap was constructed in such a way that it can be used with any non-Temperature Technology data, so long as the data fits the specific text file format required by Dymap.

TempReport is the new software for the new T-TEC RF wireless data loggers. It includes basic functions like adding a logger in to the system; removing the logger; starting the logger; stopping the logger; downloading the logger; viewing data from the logger -- including past missions; setting and changing alarms -- including emails and phone numbers for SMSs. It also includes functionality to reset the relay on the Gateway, settings (for emails, SMSs, cloud subscription, MQTT, backups, passwords); logger secuirty - passwords and permissions for various users.

It also has the ability to set when downloads should happen automatically, either at set intervals or at a set time. This can be useful if you know that all the trucks with the data loggers on board will be back in the yard by 6pm.

And separate to logging intervals are the data updates. These are the temperatures (or other) that are presented on the screen so that the user can see how the logger is going. Of course, the faster the interval, the shorter life of the battery.

Alarms will be displayed on screen, in red flashing exclamation marks, the background of the specific logger will turn red and notifications will appear in your notification tray.

If you are in the neighbourhood, please feel free to stop past and get a demonstration.

If TempReport is running on a computer that has Internet access, then TempReport can send the data out either to a T-TEC Cloud (installed on your own server or Temperature Technology's via the Internet) and/or to a MQTT broker.

T-TEC Software version 15.7: SetupT-15.7.exe:

This version provides a fix for USB 06 cables with versions less than 1.4 and removes the appearance of a driver installation file (the driver preinstalled just fine).